Feasibility Study of an Ice Cream Manufacturing Business Plan

Melaku Tafese Awulachew*

Chemical Engineering Graduate Program, Addis Ababa Institute of Technology, Addis Ababa, Ethiopia.

*Corresponding Author

Melaku Tafese Awulachew,

Chemical Engineering Graduate Program, Addis Ababa Institute of Technology, Addis Ababa, Ethiopia.

Tel: 0924621018

E-mail: melakutafese12@gmail.com

Received: April 28, 2022; Accepted: May 31, 2022; Published: June 30, 2022

Citation: Melaku Tafese Awulachew. Feasibility Study of an Ice Cream Manufacturing Business Plan. Int J Food Sci Nutr Diet. 2022;11(5):609-619.

Copyright: Melaku Tafese Awulachew© 2022. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

This project is aimed to study a feasibility for the establishment of a medium sized frozen plant ice cream manufacturing company

at Sendafa town, Ethiopia. Ice cream products represent a growing market opportunity, within the global health and wellness

market, for food manufacturers that develop consumer-led additional option products to the current available products

with added value levels, which ultimately gain consumer acceptance like many other firms all over Ethiopia. Ice cream is a frozen

blend of a sweetened cream mixture and air, with added flavorings and one of the popular dairy products among consumers

of all ages. Its textural attributes were the key factors determining the market success of the product. It is a microcrystalline

network of liquid and solid phases. One of its compositional contents, fat, also exerts good effects on body, texture, palatability,

flavor intensity, emulsion formation and maintenance of melting point. If fat contents exceed a specific usage concentration,

they cause faster meltdown of ice cream along with destabilization and agglomeration of fat droplets. Higher overrun results in

collapsing of air cells ultimately shrinkage of structure occurs. Hardness might also reduce as a result of smaller ice crystals due

to high overrun values. Fiber addition causes the binding of free water hence flow rate gets reduced and consistency coefficient

as well as viscosity enhanced. Binding of water results in less availability of its molecules; freezing point rises and melting point

decreases. It is much critical to control the balance ice cream properties by maintaining its structure, texture and body. It is a

best carrier for fruit fiber, chunks, purees, paste, concentrates; milk and whey isolates and concentrates; egg, egg yolks and their

products; different flavorings, nuts, chocolate, probiotics and yogurt. So far, it is important to maintain its solid contents and

structure with balanced proportion of ingredients. Generally, Payback period is less than one year. A shortest payback period

has less risk than with the project with longer payback period. The payback period is often used when liquidity is an important

criterion to choose a project. The project is risk free and feasible project with high demand.

2.Introduction

3.Materials and Methods

4.Results and Discussions

5.Conclusions

6.References

Keywords

Ice Cream; Strategy; Properties; Technology And Engineering; Market Evolution; Market Analysis.

Introduction

Ice Cream is a frozen emulsion of air bubbles, ice crystals, milk

fat globules, colloidal proteins, and gums suspended within viscous

syrup, the continuous phase. It is a dairy product prepared

by pasteurization, homogenization, and aeration and freezing that

has been maintained at uniform consistency. Composition of ice

cream is comprised of sugar, fat, emulsifiers, stabilizers, water, egg

and eggs products, corn syrup, dextrose and flavors. It is a threephase

network consisting on air, solid and liquid in final product.

Liquid phase contains ice crystals in embedded form and air cells

in dispersed form. Milk proteins, soluble and insoluble salts, fat

particles, stabilizers and sugars are also present in liquid phase.

So it is a very complex physiochemical food system. Ice cream is

categorized in dairy frozen desserts in which frozen confections,

water ice, sherbet, frozen custard, pare vine like products, ice milk

and mellorine are included.

The type of milk protein can affect the stability of the air cells

in ice cream. Sodium caseinate contributes to aeration and emulsification

of ice cream mixes, but it does not function the same

as micellar casein [4]. Although it increases the stability of air

cells, it may render the emulsion so stable that adequate churning

does not occur in the freezer. As with fat, proteins have little

effect on freezing point except as they displace water. Milk

proteins are hydrated, and the degree of hydration increases during

high-temperature pasteurization because of the unfolding of

protein structures. Therefore, high heat treatment may be used to minimize or eliminate the need for stabilizers in frozen desserts.

Freeze-concentration of proteins in ice cream greatly increases

the viscosity of the unfrozen phase, and this has a great effect

on ice crystallization, ice crystal stability, and solute mobility [3].

Sugar alcohols are used to replace conventional sweeteners in

sugar-free frozen desserts. Because they have a much lower glycemic

index than sugar and corn sweeteners, they provide solutions

for formulating frozen desserts for insulin-dependent diabetics.

Included in this group of mono- and disaccharide sugar alcohols

(the polyols) are sorbitol, mannitol, xylitol, erythritol, lactitol,

maltitol, isomalt, and some related hydrogenated starch hydrolysates

(Nabors, 2001, 2002). Stabilizers are added to ice cream

for the primary purpose of affecting the texture. The consumer

usually desires a velvety-smooth product with a moderate rate

of melt, limited coldness, and a uniform distribution of particulates.

Stabilizers contribute to these properties by absorbing water

(therefore swelling) and limiting its migration, increasing viscosity,

adsorbing to air cell lamellae, and, in some instances, forming

a gel-like structure. At high concentration, they interact and become

entangled with each other, greatly modifying the rheological

characteristics of solutions. Stiffness added by stabilizers to ice

cream exiting the freezer barrel promotes easy cut-off of extruded

products and efficient packaging. The major contribution to

quality is the retardation of growth of crystals of ice and lactose.

The amount of natural emulsifier in an ice cream mix is fully adequate

to stabilize the newly formed globules, the rate of agglomeration

of these globules is usually too low to provide the most

desirable ice cream structure. When emulsifiers are added, the native

globule membrane is substantially displaced by the emulsifiers

and adsorbed proteins, and the surface area on the fat globules is

increased markedly. The extent of adsorption of these molecules

depends on their concentrations and individual physical properties

[5]. The Objectives of this study is to assess the feasibility

study of ice cream manufacturing plant in Ethiopia Product.

Ice Cream Manufacturing Project Strategy

The project strategy is to compute and penetrate the local market

in the sector of ice cream industry with another option of high

quality and hygienic product at reasonable prices with short- and

long-term goals. It is intended also to maintain a significant price

parity between the competitors so as to increase its market share

of the food industry.

This project idea is being promoted in line with the following government

industrialization and general development policies: the

Government policy on GTP’s plan on agricultural-processing and

industrialization is pertinent to this first; the Ethiopian commodity

market in a transparent, fair and sustainable manner that would

benefit all the actors in the value chain and the country at large.

Through the sourcing of raw materials locally within the region,

this project is therefore, envisaged to have a trickle-down effect

on employment and income generation to the local inhabitants

especially the small-scale farmers and business men and women.

Demand projection

It indicates that most of current ice cream processed products

have deficiencies with regard to meeting the current demand of

market. Hence, the coming with alternative ice cream manufacturing

product is recommended to show good option in ice cream

products.

Quality Control/ Product quality: To ensure that the ice cream

is handled in such a matter that it is safe for human consumption,

of the employees will take a safe food handlers’ course. Additionally,

the building will be approved by the health and drug administration

to meet strict guidelines for the safety of the employees

and customers.

Packaging: The packaging material used by existing producers

is selected accordingly to the customer preference and availability

in local market. Therefore, its adoption by the upcoming processing

factory has been suggested.

Product description

In this study extruded plain ice-cream product with the assumption

of: white to pink color with white plastic pails; with packaging

level of 250 gram of containment; Taste: medium sweet +additives;

Raw materials: Dairy products (milk, cream, butterfat), Sugar,

Avocado Fruit, Corn starch, Stabilizers, Emulsifiers, Water

Ingredients: Food grade additives and the range will be finding

out according to local preferences

Natural flavors of orange with mango, and colorants from bakery

ingredient suppliers.

Those the Approved additives to prevent creation of ice crystals

during production process, Air which improves ace cream’s

ability to absorb flavoring.

The current product aims to contain at least 10% milk fat, and

at least 20% total milk solids, and may contain safe and suitable

sweeteners, emulsifiers and stabilizers, and flavoring materials.

The Manufacturing and Compositional PropertiesOf Ice Cream

Blend the Ice Cream Mixture

The milk fat source, nonfat solids, stabilizers and emulsifiers are

blended to ensure complete mixing of liquid and dry ingredients.

Pasteurize Mix: Ice cream mix is pasteurized at 155°F (68.3°C)

for 30 minutes or 175°F (79.4C) for 25 sec. The conditions used

to pasteurize ice cream mix are greater than those used for fluid

milk because of increased viscosity from the higher fat, solids,

and sweetener content, and the addition of egg yolks in custard

products.

Homogenize: Ice cream mix is homogenized (2500 to 3000 psi)

to decrease the milk fat globule size to form a better emulsion and

contribute to a smoother, creamier ice cream. Homogenization

also ensures that the emulsifiers and stabilizers are well blended

and evenly distributed in the ice cream mix before it is frozen.

Age the Mix: Ice cream mix is aged at 40°F (5°C) for at least 4

hours or overnight. Aging the mix cools it down before freezing,

allows the milk fat to partially crystallize and the gives the proteins

stabilizers time to hydrate. This improves the whipping properties

of the mix.

Add Liquid Flavors and Colors: Liquid flavors and colors may

be added to the mix before freezing. Only ingredients that are liquid

can be added before the freezing, to make sure the mix flows

properly through the freezing equipment.

Freeze: The process involves freezing the mix and incorporating

air. Ice cream mix can be frozen in batch or continuous freezers

and the conditions used will depend on the type of freezer. Batch

freezers consist of a rotating barrel that is usually filled one-third

to one-half full with ice cream mix. As the barrel turns, the air

in the barrel is incorporated into the ice cream mix. Ice cream

freezers designed for home use are batch freezers. Continuous

freezers consist of a fixed barrel that has a blade inside that constantly

scrapes the surface of freezing barrel. The ice cream mix

is pumped from a bulk tank to the freezing barrel and the air is

incorporated with another pump just before it enters the freezing

barrel. The continuous freezing process is much faster than the

batch freezing process.

Add Fruits, Additives: Fruits, additives are added at this point.

These ingredients cannot be added before freezing or they would

interfere with the smooth flow of the mix through the freezer.

The ice cream at this point is soft and it is easy to mix in the additives

so they are uniformly distributed throughout the ice cream.

Mixing after freezing also prevents damage to the pieces and allows

them to remain whole or in large chunks.

Package: As desired, depending on the product.

Harden: The ice cream is cooled as quickly as possible down to a

holding temperature of less than -13°F (-25°C). The temperatures

and times of cooling will depend on the type of storage freezer.

Rapid cooling will promote quick freezing of water and create

small ice crystals. Storage at -13°F (-25°C) will help to stabilize

the ice crystals and maintain product quality. At this temperature

there is still a small portion of liquid water. If all the water present

in the ice cream were frozen, the ice cream would be as hard as

an ice cube.

Compositional Properties of Ice cream

On the basis of calorimetric measurements, 9.45cal/g contributed

from fat; 5.65 Cal/g from proteins and 4.10 Cal/g from carbohydrates.

All material is not absorbed in the body hence actually

energy derived from fat, protein and carbohydrates is 9, 4 and

4 respectively [2]. Various ingredients are available in market for

ice cream that have important effects on ice cream quality. These

ingredients can be categorized in dairy and nondairy components

from many sources. Various ingredients that affect the quality of

ice cream include sugar, fat, water, emulsifiers and stabilizers.

Sugar: Sugar either in liquid or solid dry form added in ice cream

up to 12-20% but 14-16% is the preferable level. Corn syrup can

be added to replace 45% sugar in ice cream to handle, store and

economic purposes. Among various commercially available sugar

blends, solids of corn syrups-low conversion preferred because

they don’t affect the characteristics of ice cream and enhance the

total solids. Sucrose performs various functions in ice cream including.

Functions: Optimum palatability; Maintain handling properties;

Acceptability of ice cream; Sweetens the product; Increase pleasing

sweet flavor; Enhance solid contents and viscosity; Texture

and body improvement.

Defects: Higher sugar addition causes bad effects like; Bland

taste due to lacking sweetness; Mask desired flavor; Soggy ice

cream above 42% TS; Freezing point depression; Freezing slow

down; Hardening require low temperature.

Total solids: Total solids include the sum of all solid and dry

ingredients of ice cream. Fat, sugar, stabilizers and emulsifiers all

contribute to total solids. Water is replaced by total solids in ice

cream mix. Properties of ice cream are specially improved by the

addition of solids of buttermilk and egg yolk, sweet cream and

eggs.

Functions: Texture and body improvement; Whip ability improvement;

Freezing point reduction; Increase overrun with increased

total solid (TS)

Defects: Decreased cooling effect during summer associated with

increased TS; Soggy and heavy structure with TS up to 40-42.

Water: Mostly ignored but very influential component present in

ice cream air and water. Water maintains the continuous phase in

ice cream either by adding as solid or liquid form. Products from

dairy origin must be purified while it is expected that water of

milk source has been cleaned already during its passage and excretion

from memory glands.

Functions: Act as solvent; Provides liquid medium, [2].

Air: During ice cream preparation, overrun is created by incorporating

air in mixture to enhance the volume. Quality of ice cream

is influenced by amount of air incorporated. Quality of product

can be controlled by uniform addition of air. Air quality itself

is maintained by filters installed in freezers. Emulsifiers, fat and

protein in unfrozen state cause the stabilization of air and water

interface by forming thin film. Fat globules, ice crystals and water

from the emulsion and entrap the air.

Functions: Increase the volume; Meeting legal standards; Increase

profit; Product and quality control and Affect quality.

Defects: Air incorporation above certain level causes defects in

ice cream; reduced ice crystals size; Reduction in melting point;

Low hardness for the injection of nitrogen instead of air, various

researches have been performed. It was reported that rate of oxidation

was reduced with incorporation of nitrogen [7, 8].

Stabilizers: Basic types of stabilizers added in ice cream are of

two sources; Animal source (gelatin from bones and calf skin),

Plant or vegetable source (gums (agar-agar, carboxymethyl cellulose,

sodium alginate, acacia, oat, carrageenan and karaya)). Water

binding capacity of stabilizers is very high and added in small

quantity hence effect on flavor and product value is inconsequential.

Total solids, processing machine, stabilizers properties and

some other factors affect the usage of stabilizers.

Functions: Smoothens the texture; Provide body to the product;

Enhance viscosity; Freezing point not affected; Prevent from texture

coarsening; and Provide resistance during melting.

Defects: Restrict whip ability; Heavy and soggy structure; Undesirable

melting properties

Emulsifiers: During manufacturing of ice cream, emulsifiers are

added to smoothen the texture and thorough distribution of air

cells. Mono and di-glycerides are most common emulsifiers used

in ice cream plants. Emulsifiers are not be used more than 0.2%

on weight basis. Polysorbate and sorbitan tristearate up to 0.1%

are now allowed in dairy products as safe.

Functions: Stiffness to body and smoothness of texture; Reduction

in time of whipping; even whip ability properties; and

Smaller uniformly distributed air cells.

Defects: Emulsifiers when used in excessive quantity because defects

like slower melting, Textural and body defects.

Egg yolk: It is highly valuable in foods and helps in other flavors

blending for desirable properties. Ice cream cost is increased by

egg yolk addition. It provides desirable flavor to ice cream but if

product of egg has any off flavor that can be easily detectable in

ice cream with egg. Protein and lecithin complex in egg yolks is

highly preferred in mixes where total solids are lowered and prepared

with butter oil or butter.

Functions: Delicate characteristic flavor; Texture and body improvement;

Viscosity increase; and Improved whip ability.

Defects: Off flavor in egg yolk detectable in final product

Flavors: Flavor can be easily mistaken as taste or feel sensation.

It is very important ice cream property and resulted from mixed

flavor of all ice cream components. Individual taste of any ingredients

has effect on “flavor blend” or “specific flavor” so it makes

difficult in detection of specific ingredient effect on ice cream

flavor. Important properties of flavor are intensity and type. They

may be mild or harsh. Harsh flavors at even low concentration

soon turn monotonous but mild flavor can be blended easily and

at higher intensity they don’t turn into monotonous. So delicate

and mild flavors are generally preferred. Flavor must be detected

easily and provides refreshing taste in all conditions.

Properties of balanced ice cream mix

A mix is named balanced if it has all ingredients or components

proportion in a way that results in fine and desirable ice cream. If

defects are present, they may not be eliminated by changing proportion

of constituents and not resulted from poor mix balancing.

Such defects are; Flavor rancidity, Lacking of uniformity in

color, Base flavor, some defects that resulted from poor balancing

but can be corrected by alteration in mix proportion are; Insufficient

fat concentration and richness lacking, Insufficient flavors

percentage, Sandiness due to Weak body due to less stabilizers

and TS [2].

Raw Materials of Work Plan

The ingredient and product mix of the current ice cream manufacturing

work plan.

Ingredients: Fruit

Fresh Fruit: The majority of the fresh fruit that will be included

in making the ice cream will be added to market inventory periodically

throughout the summer months as the fruit ripens. Upon

ripening, the following fruit required to make the ice cream will

be purchased from local market and or directly from farm agricultural

linkage.

Process Fruit: Wash, pit, and sort Dwarf Sour cherries using

cherry pitter and sorting table. The cherries are placed on the

sorting conveyor which carries the cherries to the pitter where

they will be sorted and de-stemmed. As the cherries reach the end

of the conveyor they will fall into a basket at the pitter. The cherries

will then be loaded into the pitter and come out in front of

the packing table. At this table the pitted cherries will be vacuum

sealed before being taken directly to cold storage: Wash, peel and

core Avocado; Wash and cut banana and Wash and sort limon.

Ice cream mix

The general composition of an ice cream mix is as follows (Agriculture

and Agri-Food Canada, 2007) [1]: Milk fat: >10% - 16%

by legal definition, ice cream must have greater than 10% milkfat,

and usually no higher than 16% fat in some premium ice creams:

Milk solids-not-fat: 9% - 12%. This component is also known as

serum solids and contains the proteins (caseins and whey proteins)

and carbohydrates (lactose) found in milk: Sucrose: 10%

- 14%, Corn syrup solids: 4% - 5%, Stabilizers: 0% - 0.4%, Emulsifiers:

0% - 0.25%, Water: 55% - 64% and Fruit: 28% - 40%. The

ingredients in an ice cream mix that are required to supply the

desired components of the ice cream are chosen on the basis of

availability, cost, and desired quality. The current manufacturing

industry have in line with ice cream mix as in range above product

formulation.

Location and Site of The Proposed Project

Location of the envisaged integrated ice cream is selected based

on a two-stage Location and site selection procedures. The first

stage involved identifying potential project locations, and prioritizing

and selection of appropriate one based on critical project

selection criteria. The project location determining factors considered

in the study are supply of raw materials and inputs, access

to market, availability of skilled and unskilled labor, infrastructure

such as road, electricity and telephone line, availabilities of social

amenities – hospitals, schools, training centers and residence

housing, etc. The second stage of project location and site selection

procedure involved – identifying alternative project locations

within the selected project location and selection of the optimum

project site from the proposed sites.

Location selection

Plant location refers to the choice of a geographical area for setting

up a plant. The location of a plant is a strategic and long-term

investment decision that, if once made, is difficult to change and

that causes considerable loss. Location has a strong and long-term

influence on the success of the plant; therefore, due care has to

be exercised for selection of optimum project location. Various

determining factors have to be taken into account. In process of

the project location selection, the Consultant has adopted two stage selection processes for the envisaged plant. The first stage

is the identification of potential geographical locations based on

the assessment of critical project requirements. The second stage

involved selection of the best location from the potential locations

identified using different selection criteria and as well as established

rating scale.

Site selection

First Stage of Potential Location Selection: During the first

stage plant location selection, critical project requirements of the

envisaged plant were identified, and possible potential locations

were identified based on the availability of these critical project

requirements. The location to be selected for the commercial ice

cream manufacturing industry has to fulfill the key requirements

identified as essential or critical for a feasible and viable implementation

and operation of the plant. These critical requirements

of the envisaged project comprise of raw materials supply, supply

utilities such as water and electricity, labor, land, road/transport

facility, and other necessary infrastructures. These critical project

requirements are discussed briefly hereunder. Accordingly, around

integrated Hawassa industrial park, towns of Addis Ababa city,

Sendafa towns were proposed as potential candidates.

Second Stage of Potential Location Selection: The second

stage of selection of a specific location among the identified

potential locations for the envisaged ice cream processing plant

involves the following Procedures: Identification of manufacturing

(selection criteria); Assigning weight for each factor identified

above according to the relative importance of the factors for the

installation and operation of the envisaged mini brewery processing

plant; Finally, the identified potential locations are ranked in

a scale constructed in such a way as to magnify the relative importance

of the location for the installation and operation of the

plants. Each factor is given a rating score, which could be high,

medium or low. Multiplication of factor weight with the corresponding

rating score yields weighted average (rating index) for

each location. By so doing, the location with the highest rating index

is selected for the installation of the plant. Accordingly, from

the four proposed potential location candidates Sendafa towns

was selected as an optimal project site.

Technology and Engineering

Technology

The technology selection for the main product ice-cream compared

medium commercial technologies. Ice Cream manufacturing

plant processes are based on a common, yet modern approach

of mixing, pasteurization, homogenization with continuous agitation

and to get consistence yield. Processing operations for ice

cream can be divided into two distinct stages: mix manufacture

and freezing operations. Ice cream mix manufacture consists of

combination and blending of ingredients, batch or continuous

pasteurization, homogenization, and mix aging. The Production

steps of Ice cream are as listed below:

1. Initial mixing of materials, pasteurizing (heating at high temperature

to kill of any harmful bacteria) and homogenizing (thorough

mixing of the cream in attempt to break down any fat globules

until the mixture is perfectly smooth and uniform).

2. After the addition of flavors, colors and fruit purees, mix is left

to stand for around four hours to cool down.

3. Special barrel freezer machine then takes the mix and gradually

freezes only one part of the water crystals making the mix harder.

During the same time, machine also pumps clean air into the ice

cream, which by the end will hold over 50% of the ice cream

volume. Without that air in its structure, ice cream would be hard

as an ice cube.

4. Semi frozen mixture is then introduced with the final mix of

toppings, such as fruits, nuts, sweets or biscuit mix.

5. At the end, ice cream is packaged and blast-frozen to the temperature

between -30 and -40 degrees Celsius.

Engineering

Technical Assessment: The major components of the formulation

ice cream manufacturing industry are the machinery and

equipment of the ice cream processing and buildings and the civil

works which take the highest portion of the investment costs. In

addition to the ice cream manufacturing machineries and equipment’s,

there are facilities without which the successful operation

of the envisaged project cannot be accomplished. These facilities

include land, utilities, workshops, water and wastewater treatment

plants, etc. and human resource. These are briefly described below.

a) Land: the estimated area requirement for the envisaged project

is about 1.5 Hector as part of an integrated processing plant that

would be established for Ice cream manufacturing. An additional

area of 1.5 Hector will be reserved for future expansion of the

formulation plant.

b) Water: the demand for water in the Ice cream processing plant

is quite different. Some water is used for cleaning, human consumption

as well as for gardening. Water is available from the

Municipality of Sendafa town.

c) Electric Power: the power requirement for the operation

of the plant machinery and equipment is estimated at 250 KW

while about 10 KW is sufficient for internal and external lighting

requirements. Accordingly, a transformer with a capacity of

325 KVA is required for the ice cream manufacturing from where

power is sent to the distribution / control panel. Power is used at

a rated voltage of 100V for most of the operation of the machinery

and equipment in the processing plant. Moreover, a standby

diesel electric generator of 31.125 KVA will need to be installed

for safe shutdown of the plant and to maintain continued power

supply got lighting and communication purposes.

d) Compressed Air: the plant shall have a compressor for generation

of compressed air with air drying system to ensure low

dew point such that pneumatic control systems operate safely.

Marketing and Customer Analysis

Competitive Analysis

Relatively of homemade ice cream producers in Addis Ababa, but

many of them do not produce on a large scale. The threat of entry

into this industry is relatively high considering that small-scale

ice cream producing equipment can be purchased at a reasonable price and there is a wide array of types of ice cream that can be

made. The power of buyers of ice cream in this market is moderate

to high as ice cream is a price elastic product and buyers can

easily switch between producers. To limit this power, suppliers of

ice cream must target buyers who will purchase large quantities of

ice cream, and in turn this will create brand loyalty. The power of

the suppliers of ice cream is moderate due to seasonal demand for

ice cream and changing consumer preferences, but premium ice

creams command higher prices. There is also a high threat of substitutes

in this industry as there are many types of ice creams, ice

cream products, and multiple locations to purchase them from.

Thus, competitive rivalry in this market is high as ice cream is in

the maturity stage of its product life cycle and needs to be positioned

to a niche market in order to gain market share. Sendafa

towns competitors include any of those ice cream producers who

have ice cream products available for sale in Addis.

Customer Analysis & Segmentation

Ice cream producers must stay competitive because ice cream

consumers tend not to be very loyal unless purchasing ice cream

in large quantities for conventions and other functions.

Target Markets: The social community event segment includes

local fairs, weddings, and other community banquets. Both this

segment and the hotel and convention center market allows for

ease of entry with contracts and minimizes costs through bulk

sales.

Product Features: Good ice cream is a homemade product that

can easily be tailored to suit individual tastes and preferences. The

inclusion of locally grown fruit and milk products relates to positive

aspects of supporting Saskatchewan made products.

The Opportunity: Therefore, must be positioned as offering a

unique product with high quality and premium prices reflecting

this. The product must be positioned in a manner so that customers

will see this company as providing a flexible service that can

tailor the ice cream to meet individual needs.

Marketing Strategy

Key Planning Assumptions

provides a unique and adaptable product that fits well into a

market where consumers are looking for a quality local ice cream

product they can tailor to their needs

will strive to capture off-season sales through the superior quality

and taste of their product that will leave customers desiring the

product in winter months

will target the segment of the market that values quality over

price

Targeting the upscale restaurant, hotel, and convention centers

to design their own signature ice cream will differentiate from

their competition.

Channels of Distribution

A local ice cream supplier and the inventory travel time between

the ice cream processing facility and the final destinations will be

minimal. Consumers will be using contracts to purchase ice cream

and this will ease distribution as there will not be a set route of

distribution each week. A Freezer Van will be purchased to allow

for ease of distribution.

Pricing Policy

It will be chosen a market-based approach to its pricing policy.

Marketing Plan of the Marketing Mix (4 P’s)

Products: The current product will sell 250L quantities of premium

ice cream. The ice cream will be packaged in white plastic

pails. Each pail will have a label listing the company name and address,

the product name, the net quantity in the pail, a best before

date, a list of ingredients, and the company’s logo. Nutritional

information will be provided on a hand out sheet.

Pricing: The product will target a high-end use market via hotels,

upscale restaurants and convention centers. The ice cream will be

priced at $1.25 for a 250ml tubs of the premium product. The

product will be sold in a very competitive, but profitable market.

The intensity in which the manufacturing company will penetrate

the premium contract market for ice cream will create consistent

profitability for the business.

Promotion: The ice cream manufacturing industry will employ

a variety of promotional techniques. Pamphlets, websites, Mainstream

media and face-to-face interaction will be the focus. Along

with these techniques, sampling will be a way in which the company

can acquire new clientele. Pamphlets will allow customers

to learn more about the ice cream selection and image. A website

will be constructed to allow potential and existing customers of

the sector to place orders, view product information and discover

the image of the current particular product. Costs will be associated

with this website to keep it secure and functioning properly.

Face-to-face selling will also allow to a personal connection with

their customers.

Place: The geographical target market includes all of Sendafa

town, with an initial emphasis on high-end restaurants, hotels and

conventions centers in and around Addis. The product will distribute

their product to the target market in Addis Ababa and area

by means of the delivery vehicle purchased.

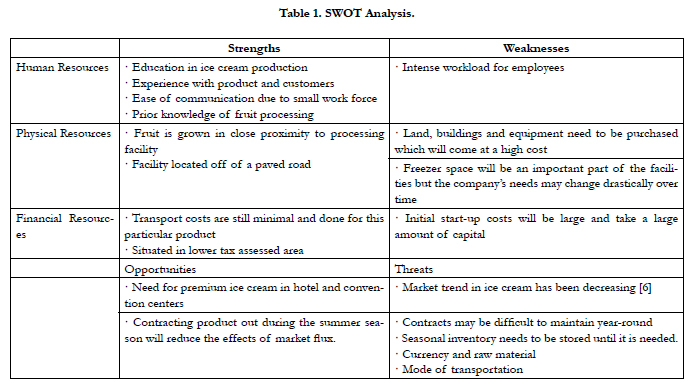

Strength Weakness, Opportunity and threat (SWOT) Analysis

Table 1

Financial Analysis

Building and civil work construction

A building permit must be acquired before this building can be

erected. The cost of the building permit is included in the cost of

the main processing facility. This building will fall in to both the

agricultural and commercial tax levels. Therefore, the building will

have multiple tax designations and each of these classifications

corresponds to different tax levels.

Infrastructure Development

The building will encompass all fruit processing and storage as well as all of the ice cream processing equipment and storage. It

will be a serviced building with heat, water, and sewer. A walk-in

freezer, including floor and recessed door, will be installed in this

building. All processed fruit and ice cream will be stored in this

freezer. A large cooler will store the ice cream mix and other processed

fruit that may need to thaw prior to beings used to make

the ice cream. This building will also house a cherry pitter, a fruit

sorting table, and a batch freezer which is used to make the ice

cream. Additionally, a large three compartment sink is included

in the floor plan, which is required by Public Health in order to

properly wash, rinse, and sanitize equipment in order to meet

compliances for health regulations. Following approval, a representative

will come to inspect the building and follow-up with

periodic visits to ensure that all health regulations are followed in

accordance to set standards.

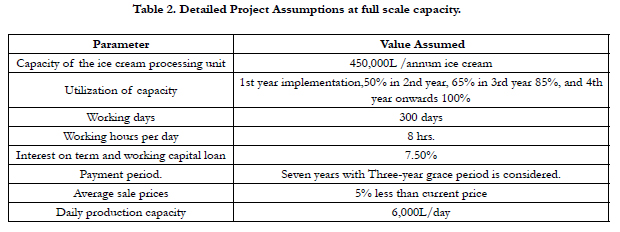

Manufacturing capacity and production program

The ice cream manufacturing industry is formulated with certain

appropriate assumption and design to achieve 50% and 65%, 80

%, 100% capacity utilization rate in the first, second and full capacity

will be attained in the third year and onwards.

Assumption@ full capacity of working:

Working day per year =300days;

The Capacity = 250L/batch, six batch ice cream per day;

Amount of fruit required annually = 75Kg*6 batch/day*300

working days/annual = 135,000Kg /year and Cream =

250*10%*6*300 = 45,000Kg/year;

Non-fat milk= 250*10%*6*300= 45,000Kg/year;

Sugar = 250*10%*6*300 days = 45,000 kg/year; Corn=

250*4%*6*300 = 18,000 Kg/year;

Additives = 250* 0.3*6*300= 1,350 kg/year; Water =

250*60%*6*300 = 270,000L/year.

Annum Capacity of the ice cream processing unit= 250L/batch*6

batch/day*300 working days/year = 450,000L/year

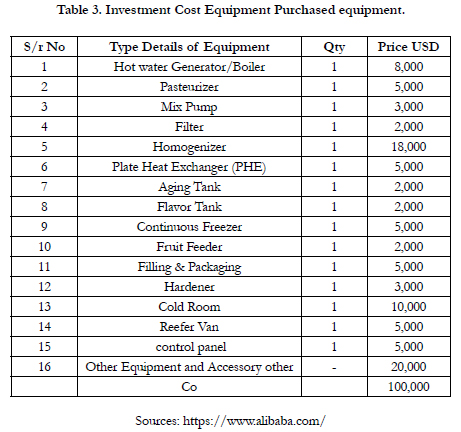

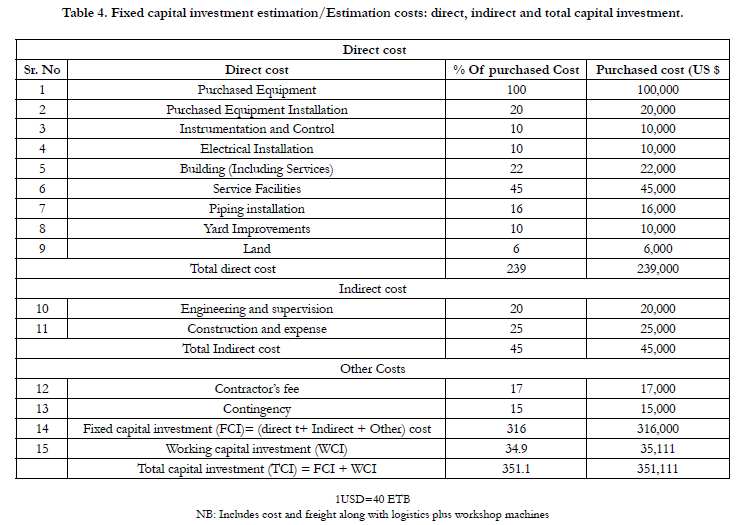

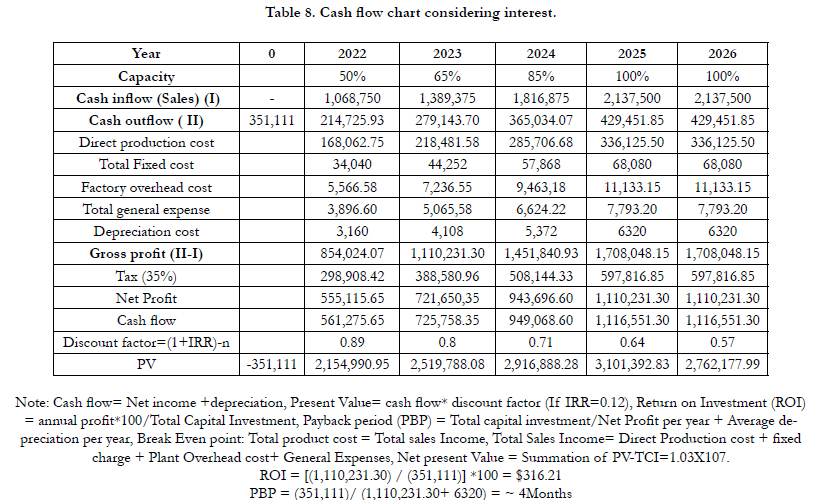

Cost of Machinery and Equipment: Based on their size and material of construction of each piece of ice cream processing equipment’s, the purchase cost is estimated (Table 4) in appropriate equipment manufacturing companies, that were considered essential pieces of equipment needed in order to carry out the complete ice cream process. A list of these pieces of equipment, their respective manufacturers, and price can be seen in table 3. Fixed Capital investment estimation: The required fixed capital investment for ice cream processing industry is estimated from the total purchased equipment cost using the equipment cost ratio method by considering it as solid-fluid processing plant.

Table 4. Fixed capital investment estimation/Estimation costs: direct, indirect and total capital investment.

Total Product cost estimation:

Total Product Cost = Manufacturing Cost + General Expenses;

Manufacturing Cost = Direct Production Cost + Fixed Charges + Plant Overhead Costs

General Expense = Administrative Costs + Distribution and Selling Costs + Interest

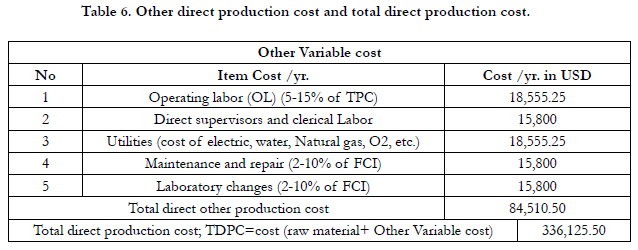

Direct production cost: Direct cost = Raw materials + utilities + operating labor + Direct supervision +maintenance and repairs + operating supplies + Laboratory charges

NB. Direct supervision and Laboratory charges are not considered.

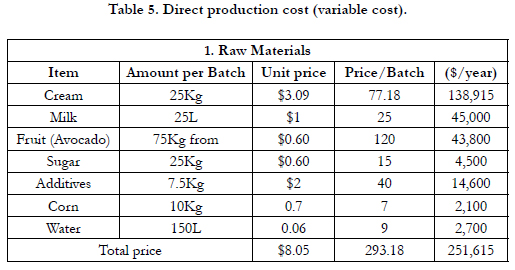

Main Raw materials cost: The major raw materials used in production of ice cream are dairy inputs (cream, milk), fruit, mix ingredients/ additives, water. From the material balance the raw materials used during mixing was calculated, in this specific project we follow an estimate for material. Therefore, the annual required raw materials with their assumed prices can be shown in the following Table 5.

Man power requirement: The estimated cost of man power of permanent staffs and others causal staffs is calculated from fixed capital investments Cost @ 13% of FCI= 316,000*0.13= $41,080/year. Note: Among employees, Manager, 4-skilled, workers are permanent staffs only and others are causal staffs.

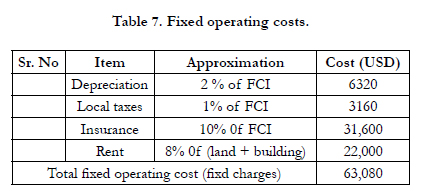

A. Fixed charges

Fixed charge includes Depreciation, Local tax 35%, Insurance and rent

B. Plant overhead costs

It is about 60% of operating labor

Plant overhead cost = 60% of operating labor = 18,555.25*60%= $11,133.15

Manufacturing cost = Total (direct production +fixed charge + plant overhead) cost= $348,838.64

1. General expense

In addition to manufacturing cost, other general expense is involved in any company’s operations. These general expenses are including: - Administration cost; about 15% of total product cost, Distribution and selling costs; about 10% of total product cost, Research and development cost; about 2% of total product cost, Financing (interest), about 10% of capital investment.

Total general expense = (Administration cost + Distribution and selling costs + Research and development cost+ Financing (interest)) *37% = $371,104.94*37% = $7,793.20

2. Total production cost = manufacturing cost + general expenses = $371,104.94

One bottle size = 0.25L

Annually plant production capacity @ full operation =450,000L/ year

Unit production cost = Total product cost TPC/ annual production capacity = $371,104.94/450,000L/year = $0.82/L Profit margin=30% of Unit Production Cost = $0.82/L*30%= $0.25/L

N.B. Assume 1Kg is Equivalent to 1 Litter.

Financial evaluation

Net income and return on investment

Assuming Local Gross earn of current price of the ice cream is $5/Kg. However, the price is based on the specification of the ice cream. Based on this planned to price the cost of Our product with 5% lower of the average of current price to $4.75/kg bottle & similarly 5% reduction sale for local market.

Locally total selling price (revenue) = 450,000L/year*4.75$/ L=$2,137,500

Gross profit = Locally total selling price (revenue) - total production cost = $2,137,500 - $371,104.94 =$1,766,395.06

Income tax on gross profit (35%) = $1,766,395.06*35%= $618,238.27

Net income (profit) = $2,137,500 - $618,238.27 = 1,519,261.73

% profit = net income /Total production cost = $1,519,261.73/$371,104.94*100= 409%

Cash Flow Return (DCFR): The discount flow rate of return is the return obtained from an investment in which all investment and cash flows are discounted. It is determined by setting the NPV equation equal to zero and solving for the discount rate that satisfies relation. Consider the plant capacity starting with 50% capacity at the first year and 650% capacity in the second year, third year, with 85% capacity and 100% capacity for the remaining project life. Detail manipulation and the project life summary of economic data detail is given in the following cash flow table 9 below.

Conclusion and Recommendation

The feasibility study of the net present value is positive and the

payback periods less than one year the project is acceptable and

viable for implementation. Those, the payback periods of approximately

4months apparently minimize any risk in regaining the

initial investment. The most critical determinants of the viability

of the project are NPV which in this case are adequate to avoid

any doubts about the project’s viability.

Since, the study confirmed the feasibility and workability of the

business idea. Hence, ice cream processing is a business opportunity

that is yet to be fully exploited. Therefore, as a recommendation

for those who have a potential of investing, if they run this

business idea, they can succeed.

References

- Agriculture and Agri-Food Canada [Internet]. Canada: Canadian dairy industry; c2007 [cited 2007]. Available from: http://www.dairyinfo.gc.ca/_ english/cdi/index.html

- Arbuckle WS. Ice cream. Springer; 2013 Mar 9.

- Flores AA, Goff HD. Ice crystal size distributions in dynamically frozen model solutions and ice cream as affected by stabilizers. J Dairy Sci. 1999 Jul 1;82(7):1399-407.

- Goff HD, Ferdinando D, Schorsch C. Fluorescence microscopy to study galactomannan structure in frozen sucrose and milk protein solutions. Food Hydrocoll. 1999 Jul 1;13(4):353-62.

- Krog N. The Use of Emulsifiers in Ice Cream in Ice Cream, W. Int. Dairy Fed.: Brussels. 1998:37-43.

- Marshall RT. In Marshall, RT, Goff, HD and Hartel, RW. Ice Cream. NY: Kluwer Academic. 2003;6:11-54.

- Marshall RT, Goff HD, Hartel RW. Ice cream. Springer. 2012;56-58.

- Sofjan RP, Hartel RW. Effects of overrun on structural and physical characteristics of ice cream. Int Dairy J. 2004 Mar 1;14(3):255-62.