KOCHO (Indigenous Food Of Ethiopia): A Review On Traditional Practice To Scientific Developments

Melaku Tafese Awulachew*

Ethiopian Institute of Agricultural Research, EIAR, P.O.Box 2003, Addis Ababa, Ethiopia.

*Corresponding Author

Melaku Tafese Awulachew,

Ethiopian Institute of Agricultural Research, EIAR, P.O.Box 2003, Addis Ababa, Ethiopia.

Tel: 0924621018

E-mail: Melakutafese12@gmail.com

Received: October 12, 2021; Accepted: December 27, 2021; Published: January 03, 2022

Citation: Melaku Tafese Awulachew. KOCHO (Indigenous Food Of Ethiopia): A Review On Traditional Practice To Scientific Developments. Int J Food Sci Nutr Diet. 2021;10(7):569-574. doi: dx.doi.org/10.19070/2326-3350-2200098

Copyright: Melaku Tafese Awulachew© 2022. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

Kocho is food product produced by decorticating and fermenting of enset parts. Quarter of Ethiopian population those were

inhabited in south and south western part were used as staples or co-staples food source. Kocho preparation composed of

many steps, these all steps are still performing with indigenous knowledge with traditional practices. Despite its advantages,

enset plant processing for preparation of food is time consuming, unhygienic, need long fermentation period, low in protein,

and have strong odor. Those of the uncommon sensory attributes are the results from microbial spoilage due to high moisture

content of Kocho. High moisture content supports the growth of spoilage microorganisms which in turn produce unpleasant

organic compounds. The nutritional and organoleptic qualities of Kocho could therefore, be process related. Nutrient loss and

time taking fermentation processes are common and vary from place to place. Plus, accurate understanding and introduction

of these processes in both enset growing and nongrowing regions can help to improve, standardize and increase the utilization

of the process in order to contribute to food security of the country. However, limited research was reported on preservation

of kocho by chemical ingredients and natural species, microbes involved in fermentation and spoilage. In addition, very fewer

studies were reported on effect of biochemical and role of fermentation on anti-nutritional factors degradation. Similar to

other fermented food it can inhibit growth of pathogenic bacteria, extending product shelf-life while ensuring consumer safety

and it can be stored for years. However, scientific review to show the kocho traditional practice and scientific research undertaken

in this area is found. In considering above all, this review is under taken with objective to review the traditional practice

and scientific research reported on kocho preparation. Similarly, the document tries to give a brief description of its common

Characteristics with in relation to microbial, biochemical and fermentation conditions.

2.Introduction

3.Materials and Methods

4.Results and Discussions

5.Conclusions

6.References

Keywords

Kocho; Enset; Microbes; Biochemical; Fermentation Conditions.

Introduction

Fermented kocho product is referred to as the kocho food which

have been subjected to the action of micro-organisms or enzymes

so that desirable biochemical changes cause significant modification

to the food or fermented as a form of energy-yielding microbial

metabolism in which an organic substrate, usually a carbohydrate

is incompletely oxidized, and an organic carbohydrate act

as the electron acceptor. Kocho is a traditional fermented food

product in Ethiopia and is produced by fermentation of parts of

the ‘false banana’ (Enseteven-tricosum). It is prepared from the

pseudostem and corm which is scraped and fermented in solid

state fermentation [29].

Enset is a multipurpose crop and provides food for more than 13

million people in Ethiopia (Guzzon and Muller, 2016). It's one of

the fourth agricultural systems in Ethiopia [9]. Its cultivation and

fermentation tradition are unique and important food sources for

Ethiopia. The quarter of Ethiopian population those were inhabited

in south and south western part were used as staples or costaples

food source.

Annual production of enset plant in Ethiopia is 6543 kg/ha and

4.5 million tons of kocho are available as standing stock [34].

Relative to other crops its highly productive, drought tolerate and

obtained throughout the years and stored without the need of

refrigerator [12], where it makes a major contribution to food security

of the country. Regions where enset is used as staple food

are usually less affected by the recurrent drought periods that

occur in Ethiopia [9]. The overall objective of this paper is to review the characteristics of indigenous kocho during processing

and research drawing opportunity mechanisms and pathways inter

section in correlation to microbial, biochemical and fermentation

conditions.

Literature Review

Scientific Research on kocho

Characteristics of kocho related to its processing effects such as

microbial, biochemical and fermentation conditions are the major

concern of this document.

Limited research was reported on the major areas of kocho preparation.

One of the well-studied parts was development of is reported

by different investigators on Enset with the major concerns

such as food safety and security issues [23]; Microbial dynamics

of Enset fermentation [17], microbial spoilage and accompanying

changes [18] and biochemical changes during fermentation

and the effect of altitude on microbial successions [20], chemical

composition and degradability in different morphological fractions

[32], mineral content [5] and mineral absorption inhibitory

factors, improving the indigenous processing of Kocho using different

cultivars of Enset [40], differences between the pits and

jars of Kocho fermentation [22].

In contrast, limited research reported on microbial characterization

of the fermented batter, preservation of kocho, degradation

of the anti-nutritional factors and effect of processing methods

on quality of the kocho. However, research on the energy requirements,

development of the kocho fermentation pans were

developed and reported well. Moreover, still their a gap needs

to improve and optimize of Kocho related problems and so, an

integrative approach to increase its productivity and to optimize

its shelf-life, food safety and quality of the products, among numerous

techniques, fermentation methods and addition of traditional

preservatives of plant sources are very important activities

but need to optimization. Such traditional preservatives contain

chemical constitutes with characteristic of flavors, antioxidant as

well as antimicrobial activities.

Studies on the effect of processing methods on Quality of kocho

Kocho production is done in a ground pit, at a temperature (about

30°C), anaerobic fermentation; the starter culture is taken from

amicho (formerly fermented decorticated ensetpseudosteam),

which facilitates fermentation of Kocho (used as inoculation of

microorganism). The fermentation method and duration differ

from area to area, sometimes even from household to household

(supplementary figures 2-4). According to [20], fermentation

is carried out in a pit after supplementation of a traditional

starter for about 2–5 months in regions at high altitude; while in

regions at low altitude traditional surface fermentation is followed

by pit fermentation as a two-step process continued for about

2–4 months. Traditional surface fermentation for 2–4 weeks by

supplementation of a traditional starter is common in the Gedio

zone [37].

Enset processing mainly takes place from October to early December

and occasionally from May to mid-June [8]. Enset is

usually harvested just before flowering, the preferred harvesting

time is just when the plant flowers. The time duration required to

flower depends upon climatic conditions, clone type, and management.

Hence, the flowering time varies from 3 to 15 years but is

optimally around 6 or 7 years [35].

Studies on the effect of Fermentation

Fermentation: Microbes have played an important role in human

food production through fermentation since ancient times,

originally for food preservation purposes. The technique of fermentation

has been used globally to improve nutritional, safety,

and organoleptic properties of food using different raw materials.

Also, in Africa the technique has been used as an inexpensive

method to effectively preserve and improve sensory and safety of

food [2]. The production of fermented products is based on the

microbial activity that transforms a raw material into a product

with increased sensory and nutritional value, leading to several

known general nutritional attributes, including the following: 1)

Enhanced nutritional value through the breakdown of certain

constituents and anti-nutritional factors, increased availability of

micronutrients such as iron, zinc and calcium, and the synthesis

of B vitamins [15, 19]. 2) Enhanced digestibility due to the

breakdown of indigestible oligosaccharides such as lactose and

complex polysaccharides [30]. 3) Enhanced food safety by protection

from proliferation of pathogenic microbes by the low pH

and antimicrobial compounds, which also gives the products a

prolonged shelf life [32, 11]. 4) Elimination of toxic substances

such as mycotoxins [27, 36]. 5) The fermenting bacteria serve as

probiotics, contributing to a healthy ecology of intestinal bacteria

which promotes general health [41, 24, 30].

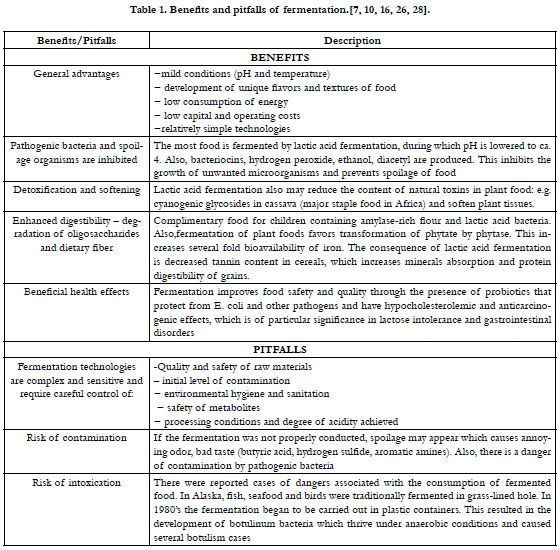

Benefits and Pitfalls of Fermentation:

Table 1.

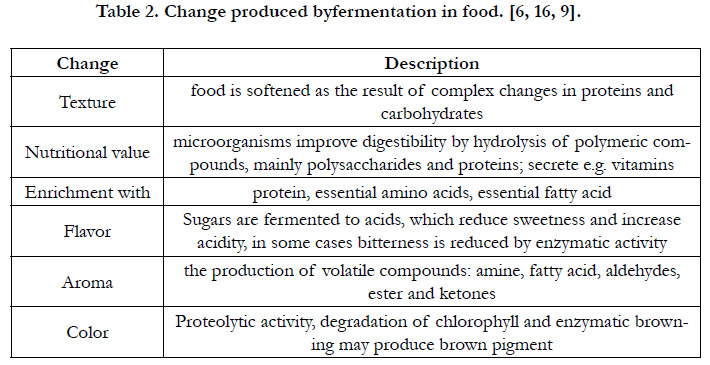

Effect on Foods: Fermentation of foods is the controlled action

of microorganisms to alter the texture of food, to preserve (by

the production of acids and alcohols) and to produce characteristic

flavors and aromas. Changes produced by fermentation in

food are discussed in Table 2.

Fermentation Feedstocks/Microorganisms:

Microorganisms that are used in industrial fermentations include: o Bacteria:Acetobacter, Streptococcus, Lactococcus, Leuconostoc, Pediococcus, Lactobacillus, Propionibacterium, Brevibacterium, Bacillus, Micrococcus, Staphylococcus.

o Yeast: Saccharomyces, Candida, Torulopsis, Hansenula

o Mold: Aspergillus, Penicillium, Rhizopus, Mucor, Monascus, Actinomucor.

Lactic acid bacteria (LAB) are naturally present in milk, fruit juice, plant products, intestine and mucosa. In fermentation products, antimicrobial effect of their acids is used. Lactic acid bacteria are divided into three groups:homolactic (Streptococcus spp., Pediococcus spp.),heterolactic (Leuconostoc spp.) and facultative (Lactobacillus spp.). Generally, Lactobacilli are stronger acid producers than Streptococci.

Most LAB produce bacteriocins, which reduce the use of chemical preservatives, e.g. Lactococcuslactisproducesnisin which inhibits growth of Cl. botulinum and Listeria monocytogenes).

Some LAB have stabilizing and viscosity forming properties. This enables us to avoid using synthetic stabilizers and emulsifiers. Yeasts are frequently minority companions of LAB and are also used to produce CO2 (in beer and breadmaking) and ethanol (alcoholic beverages). Molds are used in the production of enzymes which degrade polymeric components: cell wall polysaccharides, proteins, lipids, which is significant for texture, flavor and nutritional value of mold fermented foods.

Discussion

Studies reported on the Human Gut Microbiota

The human gut is host to millions of bacteria and it is known that

its composition is specific for every individual. However, most

can be categorized as belonging to one of three groups, based on

the predominance of either of the genera Bacteroides, Prevotella,

or Ruminococcus [3]. Gut microbiota composition of humans is

affected by changes in lifestyle and diet [14]. The intestinal microbiota

has been recognized as a vital asset for health and neurodevelopment

and is established in the first three years of life so

that its modification during this period has the potential to affect

host health and development [33] as been shown that shifts in

microbiota composition towards more favourable taxa and combinations

of taxa leads to better health, for instance by a better

functioning immune system and protection against invasion of

pathogenic bacteria via the intestine [13]. this way, a healthy gut

microbiota with good nutrition helps to prevent disease. Since traditional

fermented foods contain a mixed community of a variety

of species, they are likely to include strains with probiotic effects

that thus can have an impact to better health of their consumers.

Studies reported on Microbial Activities in Enset Fermentation

Processes

The corms of mature enset plants were used as main raw material

for the preparation of starter culture. Studies reveals during

fermentation of kocho, the value of pH was gradually decreased.

In line with this, the number of microorganisms during fermentation

of kocho was seen gradual increment. Lactic acid bacteria,

Enterobacteriaceae, spore forming bacteria and yeast are reported

as responsible microbes for acid production during kocho fermentation

[22]. At the initial fermentation Enterobacteriaceae

increased and thereafter counts of Enterobacteriaceae reached

below detectable level [39].

According to [17], on the day zero, Kocho has high moisture

content, low titrateble acidity, near neutral pH and high soluble

reducing sugar concentration when compared to the final fermentation

days of Kocho. During the initial period, Kocho contained

a diverse group of microorganisms such as aerobic and anaerobic

spore formers, Gram negative bacteria including members belonging

to the Enterobacteriaceae, lactic acid bacteria and yeasts.

In indigenous fermented foods, the microorganisms responsible

for the fermentation are usually the microbial flora naturally present

on the raw substrate [4].

It has also been indicated that Leuconostoc mesenteroides is responsible

for initiating the fermentation of Enset during initiation

period. As it was described in the previous study, because of

the activities of this species and to some extent, of Streptococcus

faecalis, the pH of the fermenting Kocho was reduced from 6.5

to 5.6. These organisms may be then succeeded by some of the

homo-fermentative Lactobacillus species. Through the activities

of the Lactobacillus species, the pH can be further reduced to

4.2. The microorganisms are also temperature dependent. For instance,

if Pediococcus cerevisiae present in Kocho, it can’t achieve

prominence in relatively low fermentation temperature between

14°-18°C. Spore-formers may be present in fairly high numbers

during the first 15 days of fermentation. The butyrous odor usually

detected during the first two weeks in fermenting Kocho is

due to the activities of certain clostridial species, and yeasts can

be also present in fairly high numbers [17].

Studies reported on Biochemical condition of Microorganisms

Microbes, in general, require an appropriate biochemical and

biophysical environment to grow and express normal metabolic

activities. Biophysical environmental factors including temperature,

pH, water activity, redox potential, and the presence of inhibitory

compounds produce a wide range of variations among

microbes’ strains [25]. The biochemical environment conditions

are made available through nutrients in the culture media. In addition

to carbohydrates (carbon source), culture media,bacteria produce

lactic acid which conserves food. i.e., Lactic Acid Bacteria

(LAB) are usually supplemented with various free amino acids,

peptides, nucleic acid derivatives, fatty acids esters, minerals, vitamins,

and buffering agents [21]. The fastidious characteristics

of LAB, the ability of LAB strains to produce acid and antimicrobial

compounds, and the variations in nutritional requirements

among LAB strains have added additional limitations and challenges

with regard to developing general growth media. In addition,

metabolites that are produced by some LAB strains may

inhibit the growth of other strains or even the same strain such

that the case of bacteriocin production. On the other hand, low

nutrient concentrations may cause fast depletion in the essential

nutrient which may negatively affect growth whereas high nutrient

concentration such as salts could also negatively affect growth

or could be insoluble in water [25].

Conclusion

The enset plant is one of the fourth agricultural systems in Ethiopia.

Its cultivation and fermentation tradition are unique and important

food sources for Ethiopia.Fermentation was traditionally

a process which enabled to preserve food and as such has been

used for centuries until present. However nowadays, the main

purpose of food fermentation is not to preserve, since other

preservation techniques are known, but to produce a wide variety

of fermentation products with specific taste, flavor, aroma and

texture. Using various microbial strains, fermentation conditions

(microorganisms, substrates, temperature, time of fermentation

etc.) and chemical engineering achievements, enable us to manufacture

hundreds of types of foods and other food acids. In such

a wide variety of products, tastes and textures, surprising is that in

the majority of cases, only two types of fermentations are used:

lactic acid and ethanolic fermentation.

The concerns of enset related study may be to gain familiarity

with a phenomenon or to achieve new insights into it and to

portray accurately its characteristics, this lead to minimize the

post-harvest loss in terms of value addition, identification of its

optimum preservative effects or associated with searching an option

to processing, packaging and related Techniques. Also, the

function of both is to change conditions, so unwanted spoiling or

pathogenic microorganisms would not grow and alter the food-

Characteristics of natural ecosystems are instead: limited nutrient

supply, long generation times, mixed populations as well as continuous

fluxes of components into and out of the system. The main reasons to limited cultivation and consumption of Kocho

could be related to uncommon inherent sensory attributes for

non-consumers, nutrition loss, long fermentation period, lack of

awareness and its short shelf-life. Sensory attributes of Kocho are

not acceptable by most of none Enset producing areas since they

are not familiar to the odor, taste and flavor of the food. Most of

the uncommon sensory attributes are the results from microbial

spoilage due to high moisture content of Kocho. High moisture

content supports the growth of spoilage microorganisms which

in turn produce unpleasant organic compounds. The nutritional

and organoleptic qualities of Kocho could therefore, be process

related. Nutrient loss and time taking fermentation processes

are common and vary from place to place. Food taboo, lack of

knowledge, experience, skills and technology in Enset cultivation,

fermentation and consumption are the other drawbacks.

References

- Abebe Y, Bogale A, Hambidge KM, Stoecker BJ, Bailey K, Gibson RS. Phytate, zinc, iron and calcium content of selected raw and prepared foods consumed in rural Sidama, Southern Ethiopia, and implications for bioavailability. J Food Compos Anal. 2007 May 1;20(3-4):161-8.

- Anukam KC, Reid G. African traditional fermented foods and probiotics. Journal of medicinal food. 2009 Dec 1;12(6):1177-84.

- Arumugam M, Raes J, Pelletier E, Le Paslier D, Yamada T, Mende DR, Fernandes GR, Tap J, Bruls T, Batto JM, Bertalan M. Enterotypes of the human gut microbiome. nature. 2011 May;473(7346):174-80.

- Ashenafi M. A review on the microbiology of indigenous fermented foods and beverages of Ethiopia. Ethiopian Journal of Biological Sciences. 2006;5(2):189-245.

- Atlabachew M, Chandravanshi BS. Levels of major, minor and trace elements in commercially available enset (Enseteventricosum (Welw.), Cheesman) food products (Kocho and Bulla) in Ethiopia. Journal of Food Composition and Analysis. 2008 Nov 1;21(7):545-52.

- Batty JC, Folkman SL. Food Engineering Fundamentals. New York: John Wiley and Sons. [This presents various process aspects of food production]. 1983.

- Bekers M, Laukevics J, Vedernikovs N, Ruklisha M, Savenkova L. A Closed Biotechnological System for the Manufacture of Nonfood Products from Cereals. InCereals 1997 (pp. 169-176). Springer, Boston, MA.

- Belay A, Hunduma T, Fekadu E, Negisho, K, Ali A. Gender based analysis of production system in Ambo. In: Chiche, Y. and Kelemu, K. (eds.). Proceedings of the workshop on gender analysis in agricultural research (pp. 27-29) Addis Ababa, Ethiopia; 2008.

- Spring A, Diro M, A Brandt S, Tabogie E, Wolde-Michael G, McCabe JT, Shigeta M, Hiebsch C, Tesfaye S, Yntiso G. Tree against hunger: enset-based agricultural systems in Ethiopia. American Association for the Advancement of Science.

- Beumer RR. Microbiological hazards and their control: bacteria. Growth. 2001;4(7.0):0-83.

- Battcock M. Fermented fruits and vegetables: a global perspective. Food & Agriculture Org.; 1998.

- Birmeta G, Nybom H, Bekele E. Distinction between wild and cultivated enset (Enseteventricosum) gene pools in Ethiopia using RAPD markers. Hereditas. 2004 Apr;140(2):139-48.

- Conlon MA, Bird AR. The impact of diet and lifestyle on gut microbiota and human health. Nutrients. 2015 Jan;7(1):17-44.

- Derrien M, Veiga P. Rethinking diet to aid human–microbe symbiosis. Trends in microbiology. 2017 Feb 1;25(2):100-12.

- Egounlety M, Aworh OC, Akingbala JO, Houben JH, Nago MC. Nutritional and sensory evaluation of tempe-fortified maize-based weaning foods. International journal of food sciences and nutrition. 2002 Jan 1;53(1):15- 27.

- Fellows PJ. Food processing technology: principles and practice. Elsevier; 2000 Jun 22.

- Gashe BA. Kocho fermentation. Journal of Applied Bacteriology. 1987 Jun;62(6):473-7.

- Gashe BA. Spoilage organisms of kocho. MIRCEN journal of applied microbiology and biotechnology. 1987 Mar;3(1):67-73.

- Hotz C, Gibson RS. Traditional food-processing and preparation practices to enhance the bioavailability of micronutrients in plant-based diets. The Journal of nutrition. 2007 Apr 1;137(4):1097-100.

- Hunduma T, Ashenafi M. Effect of altitude on microbial succession during traditional enset (Enseteventricosum) fermentation. International Journal of Food, Nutrition and Public Health. 2011;4(1):39-51.

- John RP, Nampoothiri KM, Pandey A. Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Applied microbiology and biotechnology. 2007 Mar;74(3):524-34.

- Karssa TH, Ali KA, Gobena EN. The microbiology of Kocho: An Ethiopian traditionally fermented food from Enset (Enseteventricosum). International Journal of Life Sciences. 2014 Mar 3;8(1):7-13.

- Kanshie TK. Five thousand years of sustainability?: a case study on Gedeo land use (Southern Ethiopia). 2002.

- Kort R, Sybesma W. Probiotics for every body. Trends in biotechnology. 2012 Dec 1;30(12):613-5.

- Lechiancole T, Ricciardi A, Parente E. Optimization of media and fermentation conditions for the growth of Lactobacillus sakei. Annals of microbiology. 2002 Jan 1;52(3):257-74.

- Mirbach MJ, El Ali B. Industrial Fermentation (Ch. 9). Ali MF, El Ali BM and Speight JG, Handbook of Industrial Chemistry. Organic Chemicals. New York: McGraw-Hill. 2005.

- Mokoena MP, Chelule PK, Gqaleni N. Reduction of fumonisin B1 and zearalenone by lactic acid bacteria in fermented maize meal. Journal of Food Protection. 2005 Oct;68(10):2095-9.

- Motarjemi Y, Asante A, Adams MR, Nout MR. Practical applications: prospects and pitfalls. Adams MR and Nout MJR, Fermentation and Food Safety, Gaithesburg: Aspen Publishers. 2001.

- National Research Council. Lost Crops of Africa: Volume II: Vegetables. National Academies Press; 2006 Nov 27.

- Nout MR. Rich nutrition from the poorest–Cereal fermentations in Africa and Asia. Food Microbiology. 2009 Oct 1;26(7):685-92.

- Nout MJR, Darkar PK, Beuchat LR. Indigenous fermented foods. In: Food Microbiology: Fundamentals and Frontiers Third Edition. Edited by Doyle MP, Beuchat LR. Washingon DC: ASM Press; 2007: 817-835.

- Nurfeta A, Eik LO, Tolera A, Sundstøl F. Chemical composition and in sacco dry matter degradability of different morphological fractions of 10 enset (Enseteventricosum) varieties. Animal Feed Science and Technology. 2008 Sep 15;146(1-2):55-73.

- Rodríguez JM, Murphy K, Stanton C, Ross RP, Kober OI, Juge N, Avershina E, Rudi K, Narbad A, Jenmalm MC, Marchesi JR. The composition of the gut microbiota throughout life, with an emphasis on early life. Microbial ecology in health and disease. 2015 Dec 1;26(1):26050.

- ahle M, Yeshitela K, Saito O. Mapping the supply and demand of Enset crop to improve food security in Southern Ethiopia. Agronomy for sustainable development. 2018 Feb;38(1):1-9.

- Shank R, Ertiro C. A linear model for predicting Enset plant yield and assessment of Kocho production in Ethiopia. Addis Ababa: UNDP and WFP. 1996.

- Shephard GS. Impact of mycotoxins on human health in developing countries. Food Additives and contaminants. 2008 Feb 1;25(2):146-51.

- Tsegaye Z, Gizaw B. Community indigenous knowledge on traditional fermented enset product preparation and utilization practice in Gedeo zone. J. Biodivers. Ecol. Sci. 2015;5:214-32.

- Wroe C. Bioethanol from cereal crops in Europe. InCereals 1997 (pp. 185- 189). Springer, Boston, MA.

- Karssa TH, Ali KA, Gobena EN. The microbiology of Kocho: An Ethiopian traditionally fermented food from Enset (Enseteventricosum). International Journal of Life Sciences. 2014 Mar 3;8(1):7-13.

- Yirmaga MT. Improving the indigenous processing of kocho, an Ethiopian traditional fermented food. J. Nutr. Food Sci. 2013;3(1):1-6.

- Zimmermann MB, Chassard C, Rohner F, N'goran EK, Nindjin C, Dostal A, Utzinger J, Ghattas H, Lacroix C, Hurrell RF. The effects of iron fortification on the gut microbiota in African children: a randomized controlled trial in Cote d'Ivoire. The American journal of clinical nutrition. 2010 Dec 1;92(6):1406-15.